The quality of the products manufactured by any enterprise can directly be associated with the accuracy of the instruments producing them. If the instruments are not calibrated properly, or if they are damaged and need repair work, they will surely affect the end products.

Iso calibration lists out the general requirements for the competence of testing and calibration laboratories. All the labs must adhere to service specifications developed by the international organization for standardization.

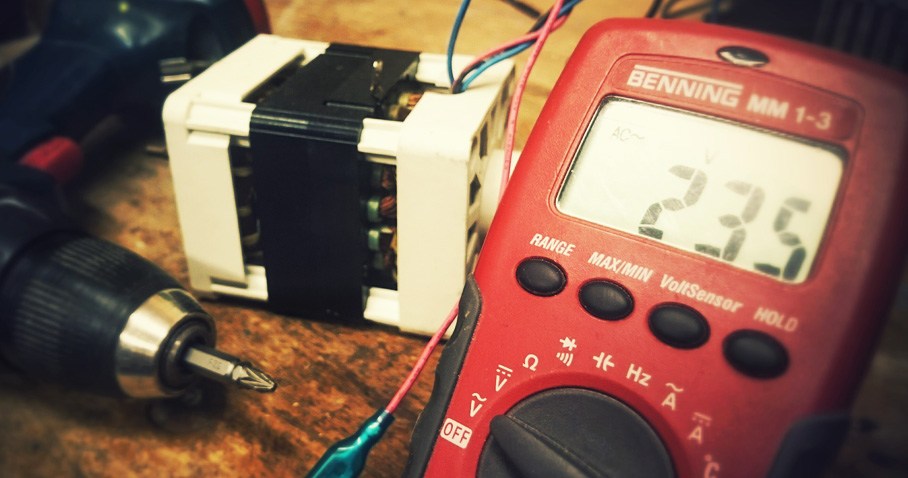

It is important to remember that instruments and equipment will not always stay calibrated. At some point, the level of calibration will go down and it will affect the final measurements and quality of the products. You must keep the instruments and equipment in excellent condition at all times. Make sure that you conduct preventive maintenance and repair, and recalibrate the instruments regularly. So how do you know when it is time to recalibrate your equipment?

A lot of different variables determine how frequently your instruments should be calibrated or re-calibrated. Let us look at some of them:

Manufacturers’ recommendations:

Every manufacturer mentions the ideal time frame of when you should recalibrate an instrument. Follow these instructions and specifications to the letter and you will face minimum maintenance issues. It is extremely important to remember that critical measurements may call for greater frequency.

Annually or biannually:

Some instruments need to be re-calibrated once or twice every year. It depends on how often the critical measurements are taken. Additionally, the amount of damage sustained by the instruments during use also plays a role.

After a damaging incident:

If any instrument was damaged in an accident, if it was dropped hard or if it sustained any kind of injury, you must calibrate it immediately. Events where the instruments sustain damage usually experience a sharp impact that directly affects their readings. Check if the calibration was altered and carry out the necessary calibration procedures.

As demanded by projects:

When you carry out certain assignments, you have to use certified and calibrated test equipment, irrespective of how big or small the project is. When assignments call for such calibration based on project requirements, you must follow it.

Before or after a major project:

Some major projects require extremely accurate measurements. This means that the instruments must be calibrated before the project starts. However, it doesn’t end there. You must calibrate all the instruments that were used after the project comes to an end. Post-project calibration will show you if the testing that you conducted is indeed reliable or not, if the correct and consistent measurements were observed throughout the project.

Semiannually, quarterly or monthly:

Some instruments, based on their use and functions, need to be calibrated frequently. If you deal with critical measurements quite frequently, it would be ideal that you conduct frequent and consistent calibration check-ups, like every month or every three to six months.